Submicron highly active phosphate is a compound anti-corrosion paint containing Zn, Al, Mo and phosphate, whose combination will increase the corrosion resistance. Through the regulation of the release speed, the phosphate reactive with Fe on the surface of steel thus form a dense protective layer which has outstanding corrosion resistance and protect the steel well.

Key technology, “submerged circulative impinging stream” is applied in the reaction process of producing this anti-corrosion material, which is the first case in China. This technology significantly enhances the micro-mixing of reactants, triggers explosive nucleation and prepare submicron highly active phosphate. This achievement meets the demand of submicron highly active phosphate material for the development of heavy-duty anti-corrosion and water-borne anti-corrosion paint market, pushing forward the update of anti-corrosion materials in Guangxi.

Innovative Highlight of This Project:

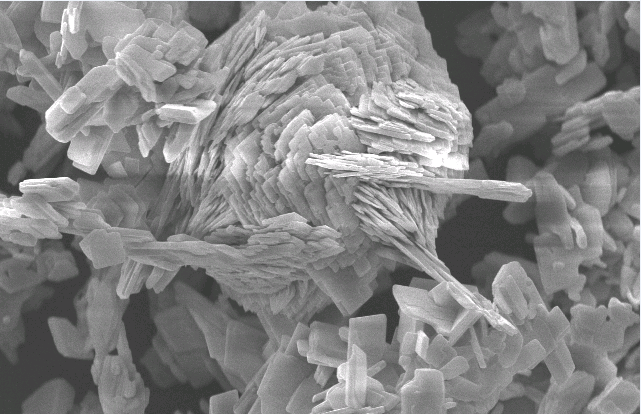

1. Developed the key technology - impinging stream reaction, which enhance the effective collision between molecules during the reaction, forming crystal nucleuses while curbing their growth thus forming submicron of stable size and distribution.

2. Developed dry dispersion of submicron phosphate technique, in which adding steric dispersion agent to prevent the clustering of molecule during the reaction. This method solves the problem of clustering during the preparation and drying and helps producing monodispersed submicron phosphate powder.

Picture 1 - impinging stream reactor

Picture 2 - zinc phosphate SEM photograph

Picture 3 - samples of submicron highly active phosphate series